0333 321 5091

01909 768 760

Mon - Fri 7:00 AM - 5:00 PM

Sat 8:00 AM - 2:00 PM

We Deliver

Nationwide

0333 321 5091

01909 768 760

Mon - Fri 7:00 AM - 5:00 PM

Sat 8:00 AM - 2:00 PM

We Deliver

Nationwide

.png) NEW FOR 2025

NEW FOR 2025  2025 PRE SUMMER SALE

2025 PRE SUMMER SALE  CLEARANCE SALE

CLEARANCE SALE  PORCELAIN PAVING

PORCELAIN PAVING  SANDSTONE PAVING

SANDSTONE PAVING  LIMESTONE PAVING

LIMESTONE PAVING  SLATE PAVING SLABS

SLATE PAVING SLABS  GRANITE PAVING

GRANITE PAVING  TEXTURED FINISH PAVING

TEXTURED FINISH PAVING .jpg) SMOOTH FINISH STONE PAVING

SMOOTH FINISH STONE PAVING  RIVEN FINISH PAVING

RIVEN FINISH PAVING  STONE CIRCLE KITS

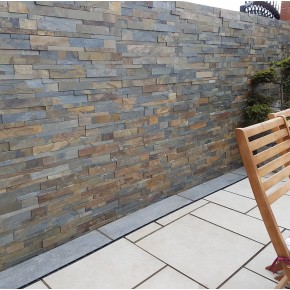

STONE CIRCLE KITS  STONE WALL CLADDING

STONE WALL CLADDING  COBBLES & EDGING

COBBLES & EDGING  DRIVEWAY BLOCK PAVING

DRIVEWAY BLOCK PAVING  LINEAR PAVING

LINEAR PAVING  BULLNOSE STEPS

BULLNOSE STEPS  WALLING & COPING STONES

WALLING & COPING STONES  COMPOSITE DECKING

COMPOSITE DECKING  COMPOSITE FENCING

COMPOSITE FENCING  COMPOSITE CLADDING

COMPOSITE CLADDING .png) COMPOSITE TRELLIS

COMPOSITE TRELLIS .png) COMPOSITE GATES

COMPOSITE GATES  SLEEPERS

SLEEPERS  ARTIFICIAL GRASS

ARTIFICIAL GRASS  SLATE ROOF TILES

SLATE ROOF TILES  WATER BLADES & FEATURES

WATER BLADES & FEATURES  DRAINAGE SYSTEMS

DRAINAGE SYSTEMS  ACCESSORIES

ACCESSORIES  GROUT JOINTING PRIMER

GROUT JOINTING PRIMER  AFTERCARE PRODUCTS

AFTERCARE PRODUCTS  SAMPLES

SAMPLES Disclaimer: Laying patterns are for guidance only. The sizes may differ depending upon the pack sizes.

Please find the laying patterns for our paving ranges below. If you have any questions or are unsure on any of the below please contact our team today.

Below we keep the same sequence you supplied, noting where porcelain and natural stone diverge (PSD 2025 guides • BS 7533-102).

| Material | Mix | Compacted thickness | Notes |

|---|---|---|---|

| Porcelain | 4 : 1 sharp sand / crushed-rock fines : OPC | 30–40 mm | Flat bed; no trowel furrows; workable ≤ 2 h |

| Natural stone | Same 4 : 1 (avoid builders’ sand); use 0–6 mm crushed rock | 30–40 mm | Full contact; no spot-/ring-bedding (avoids reflective staining) |

| Stage | Porcelain | Natural stone |

|---|---|---|

| Primer | Bonding slurry 2-3 mm (PSD Porcelain Guide) |

SBR slurry / primer (PSD Natural-Stone Guide) |

| Joint width | Exactly 5 mm (spacers) | 10-15 mm; no cross-joints on random layouts |

| Cutting | Continuous-rim diamond blade, wet-cut | Standard masonry blade |

| Sealing | Optional – porcelain is non-porous | Consider after 3-6 months to resist stains |

Sequence mirrors BS 7533 good-practice. Notes highlight where porcelain and natural-stone blocks differ (both 50 mm thick).

| Material | Mix | Compacted thickness | Notes |

|---|---|---|---|

| Porcelain blocks (50 mm) |

4 : 1 sharp-sand / cement mortar (bound system) | 35 – 40 mm | Full support; prime undersides with bonding slurry before laying |

| Natural-stone setts (50 mm) |

Grit (sharp) sand – unbound | 25 – 40 mm (after compaction) | Flexible bedding; moisture-balanced sand aids interlock |

| Stage | Porcelain blocks | Natural-stone setts |

|---|---|---|

| Typical block thickness | 50 mm | 50 mm |

| Bedding | Bound mortar bed (35–40 mm) + slurry primer | Unbound grit-sand bed (25–40 mm compacted) |

| Jointing | Flowable grout / resin, 5 mm | Kiln-dried sand, 2–3 mm |

| Final compaction | Roller or padded plate (low amplitude) | Standard vibrating plate with rubber mat |

These guide lines are informative only and not comprehensive. For more detailed information please visit www.pavingexpert.com and www.paving.org.uk

All our slabs should be laid pointing downwards. They should go on a full Mortar Bed of Sand & Cement with a Sub-base. The recommended laying ratio is 4 parts sharp sand and 1 part cement.

A quick visual guide below will show the laying process. Please note that this is for reference purpose only and all necessary Health & Safety Precautions should be taken whilst laying them.

Paving Stones Direct UK Ltd, supplies high quality, globally sourced Vitrified Porcelain Paving and Natural Stone Paving Slabs. We are the direct importers of Porcelain and Natural Stone Paving products to provide cost effective yet high quality products to home owners and contractors.

Try Our Laying Guide