0333 321 5091

01909 768 760

Mon - Fri 7:00 AM - 5:00 PM

Sat 8:00 AM - 2:00 PM

We Deliver

Nationwide

0333 321 5091

01909 768 760

Mon - Fri 7:00 AM - 5:00 PM

Sat 8:00 AM - 2:00 PM

We Deliver

Nationwide

NEW FOR 2026

NEW FOR 2026  WINTER SALE

WINTER SALE  CLEARANCE SALE

CLEARANCE SALE  INDOOR TILES

INDOOR TILES  PORCELAIN PAVING

PORCELAIN PAVING  SANDSTONE PAVING

SANDSTONE PAVING  LIMESTONE PAVING

LIMESTONE PAVING  SLATE PAVING SLABS

SLATE PAVING SLABS  GRANITE PAVING

GRANITE PAVING  TEXTURED FINISH PAVING

TEXTURED FINISH PAVING .jpg) SMOOTH FINISH STONE PAVING

SMOOTH FINISH STONE PAVING  RIVEN FINISH PAVING

RIVEN FINISH PAVING  STONE CIRCLE KITS

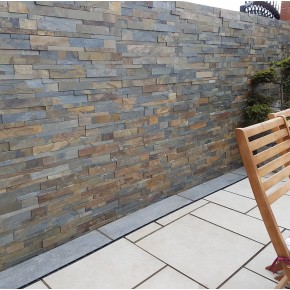

STONE CIRCLE KITS  STONE WALL CLADDING

STONE WALL CLADDING  COBBLES & EDGING

COBBLES & EDGING  DRIVEWAY BLOCK PAVING

DRIVEWAY BLOCK PAVING  LINEAR PAVING

LINEAR PAVING  BULLNOSE STEPS

BULLNOSE STEPS  WALLING & COPING STONES

WALLING & COPING STONES  GRANITE KERBS

GRANITE KERBS  COMPOSITE DECKING

COMPOSITE DECKING  COMPOSITE FENCING

COMPOSITE FENCING  COMPOSITE CLADDING

COMPOSITE CLADDING .png) COMPOSITE TRELLIS

COMPOSITE TRELLIS .png) COMPOSITE GATES

COMPOSITE GATES  SLEEPERS

SLEEPERS  ARTIFICIAL GRASS

ARTIFICIAL GRASS  ALUMINIUM PERGOLA

ALUMINIUM PERGOLA  SLATE ROOF TILES

SLATE ROOF TILES  WATER BLADES & FEATURES

WATER BLADES & FEATURES  DRAINAGE SYSTEMS

DRAINAGE SYSTEMS  ACCESSORIES

ACCESSORIES  GROUT JOINTING PRIMER

GROUT JOINTING PRIMER  AFTERCARE PRODUCTS

AFTERCARE PRODUCTS  SAMPLES

SAMPLES Take a look at our available How To Guides & Videos to help you with your paving stones installation and maintenance, ensuring the best possible finish for your product.

Full wet bed: best practice on type 1 subbase

Thin bed adhesive: best practice on concrete.

A primer should be applied to the underside of the tiles prior to placement, to ensure there is full adhesion between paving and bed. Tile spacers are a must in keeping the paving uniform.

It is best practice to open all of the packs being used for a project before yourself or landscaper starts laying the paving, this therefore ensures all the colours can be blended in naturally to create a beautiful patio. All products may have slight colour variations with tones and patterns. Porcelain batches may vary so please ensure all goods are from the same batch prior to laying.

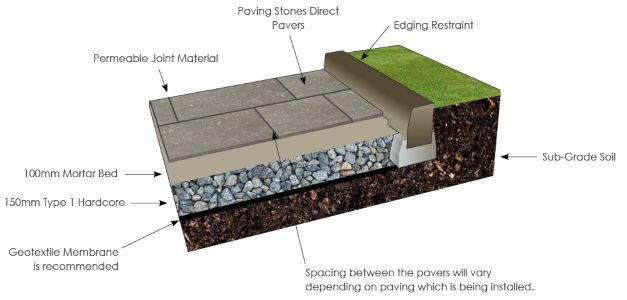

Ground preparations for natural stone and porcelain paving are almost identical. Construction components consists of:

Sometimes overlooked on its importance but choosing the correct sub base is essential in how the patio will perform later on. Geotextile should be rolled out over the area of the patio and cut to the cover the total area. A misconception is that it’s main function is to prevent weed growth. But its main purpose is to stop the sub base migrating into the sub grade. Basically, preventing the chance of settlement on the patio.

Full wet bed: Best practice on type 1 subbase

To ensure the end result matches your vision, make sure you use the right tools for the job such as a power drill with mixing attachment, bucket for mixing and trowel to spread external adhesive evenly across the wall.

Paving Stones Direct UK Ltd, supplies high quality, globally sourced Vitrified Porcelain Paving and Natural Stone Paving Slabs. We are the direct importers of Porcelain and Natural Stone Paving products to provide cost effective yet high quality products to home owners and contractors.

Try Our Laying Guide